family-owned since 1777

OUR HERITAGE

Kent Brushes has been crafting exceptional brushes for generations. From our very beginnings as a family-owned business, we have upheld a tradition of brush making that continues to define us today.

Our story is one of dedication, innovation, and resilience.

Scroll down to explore where it all began, discover milestone moments that shaped our journey, and revisit the challenges and triumphs that have helped make Kent Brushes what it is today.

KENT BRUSHES TIMELINE

-

1777

Kent Brushes is Founded

William Kent established his company, GB Kent, in London. He used to deliver his brushes by horseback. He'd lead the way, followed by a string of horses carrying his wares and his henchmen at the rear.

The business was founded, remarkably, more than 25 years before the invention of the train and the bicycle and even before iconic landmarks such as Big Ben.

-

1807

Factory Growth

His son, William Kent Junior took over the business in 1807 and moved it to a larger premises at 11 Great Marlborough Street, London, where the company stayed for the next 89 years until 1897. Charles Darwin, The Marlborough’s and the actress Mrs Siddons (the first woman to play Lady Macbeth) were neighbours and also lived on Great Marlborough St.

-

1820

Royal Approval

In the 1820s, Kent expanded and began making toothbrushes for His Majesty King George IV. These toothbrushes were stamped with the Royal Coat of Arms. Kent Brushes has had the honour of holding a Royal Warrant for nine consecutive serving monarchs.

-

1837

Brothers Align

William Kent passed away in 1836, and his brothers John James and Henry John James took over the business. from 1836 to 1854, the company was called ‘John James Kent & Co’. Queen Victoria came to reign in 1837-1901, and Kent Brushes proudly received her Majesty’s Royal Appointment.

-

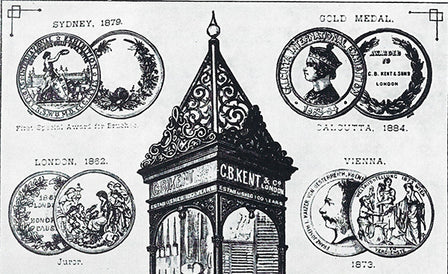

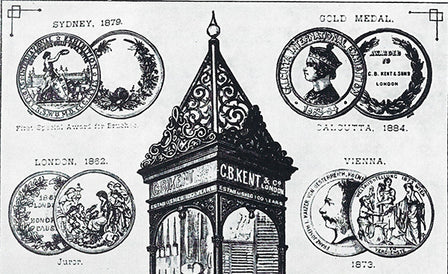

1851

The Great Exhibition

In 1851, Kent Brushes was awarded a medal for ‘Services Rendered’ at the famous Great Exhibition of 1851 in Hyde Park, London.

-

1854-1880

A New Era

John James' only son, George Barton Kent, took over the business in 1854 and renamed the business G.B Kent. Under George’s leadership, the business became a household name and expanded its international reputation. In the preface to the 1872 catalogue, GB Kent writes that the factory ‘has turned out more brushes than have been made in any other factory in the UK’.

-

1874

Raw Materials

The handles of the toothbrushes were made mainly from the leg bone of bullocks that came directly from the London bone boilers. The leg bone was the best material to use, and to keep up with demand, no less than six hundred head of cattle and over a ton of bristles were required weekly to produce 60 gross toothbrushes.

-

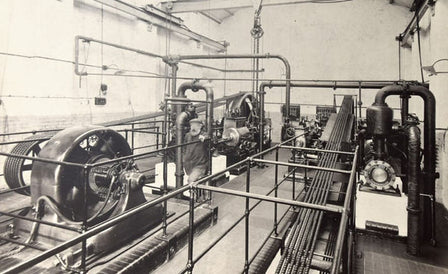

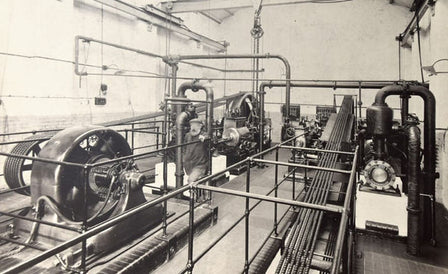

1882

Full Steam Ahead

The dawn of steam power was one of the hallmarks of the Industrial Revolution, and Kent Brushes was one of the first factories to harness it to power machines. By 1882, Kent Brushes had acquired more buildings and land across London and employed 600 staff members, with more than a quarter of them dedicated to making toothbrushes.

-

1890

Progress to Expansion

In 1882, telephones, which had just been invented, were installed at the offices and factory. George Kent died in 1890, and his three sons succeeded him, continuing his policy of progress and expansion. They renamed the Company G.B Kent & Sons.

-

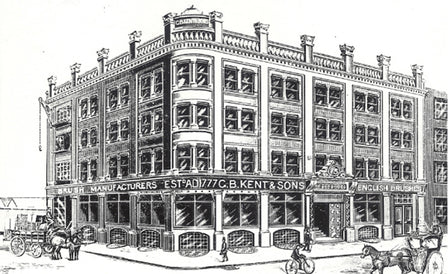

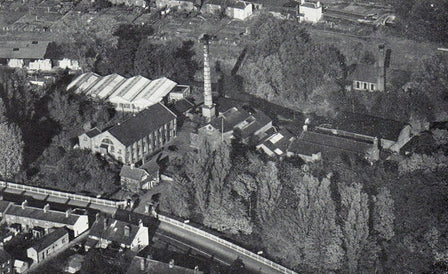

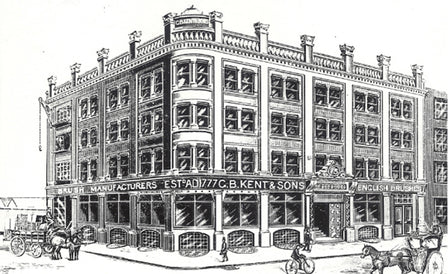

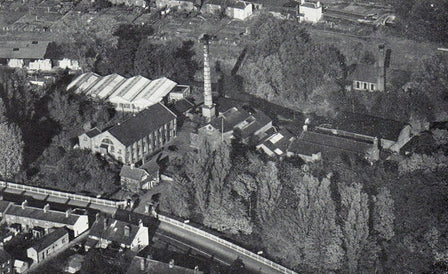

1897

Expansion

By the end of the 19th Century, Great Marlborough Street had become too small for the expanding business, and the offices and warehouses were moved to 75 Farringdon Road, a capacious six-storey building that was the largest brush warehouse in Great Britain and the company’s headquarters for the next 43 years until 1940. A second factory was built over five acres of land in Apsley, Hertfordshire, and the business remains there to this day.

-

1898

Materials

Timber and coal were delivered by barge via the canal, and deliveries included bristle from Russia, Siberia, China and India. Badger hair from Germany and the Balkans. Whalebone from the Antarctic, fibres from Mexico, Brazil and Africa. Beech, cherry, birch and sycamore from the English countryside and tropical timbers such as ebony and satinwood from the forests of Sri Lanka, the West Indies, South America and Indonesia.

-

1908

On The Road

The turn of the 20th century saw the first cars appearing on British roads, and Kent Brushes were quick to latch on to this new form of transport. Kent were one of the first businesses to start using motorised delivery vehicles, transporting their brushes to customers quicker than ever before.

-

1914

World War I

The outbreak of World War 1 saw the country unite in the war efforts, and Kent Brushes played its part, supplying hundreds of thousands of brushes to the War Office. The brushes formed a key part of a soldier’s kit, featuring a hairbrush, toothbrush, shaving, shoe-polishing and button brush. Large quantities of horse brushes were also supplied for the Army, and special toothbrushes were made for the Indian troops with wooden handles and filled with vegetable fibre as the use of bullock bone or pig bristle was against their religion.

-

1932

The Cosby Family Takes The Reins

One of the biggest events in our history took place in 1932. Having run the business for six generations, the last of the three Kent brothers passed away, and Eric. L.H. Cosby—an engineer with wide experience on both sides of the Atlantic and the inventor of the ‘Cosby hygienic refillable hairbrush’—bought the business. The Cosby Family has run the Company ever since, taking it into the 20th and 21st century.

-

1939

Second World War

The Company played its part again in the Second World War – 1939-1945, making millions of different brushes for the Army, Navy, Air Force, and Ministry of Supply. The Victoria Park Factory was damaged seventeen times during the war – but the workers showed amazing courage and endurance and carried on amidst falling bombs.

-

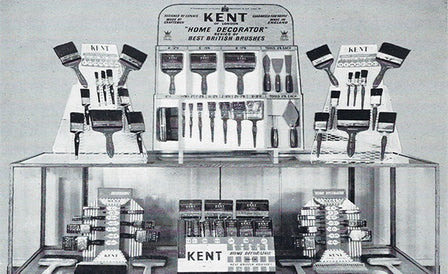

1942

Eric Junior

Eric Cosby Junior was appointed Director in 1942 after he returned from Army service. At long last, export business was re-opened in countries that had been suspended during the war, and a new factory for paintbrushes was opened in Deal, Kent. A retail shop was also opened in 1946 at 174A Piccadilly opposite the Royal Academy, where customers could see brushes being handmade.

-

1952

Plastic Power

In 1952, an issue of Preference Shares was made to the public to provide further capital for the expansion of the business and the development of plastics initiated by Eric Cosby Junior; it would mark a new wave in manufacturing for not only Kent Brushes but the world.

-

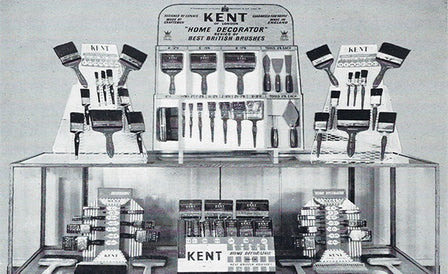

1955

New Royal Warrant

Queen Elizabeth II was crowned in 1952, and three years later, Kent Brushes became the proud recipient of the Royal Warrant as Brushmakers to Her Majesty. New, more modern sales methods were introduced, as well as new brush lines designed by Eric Cosby, including a range of wooden brushes made from the foundations of the old Waterloo Bridge and Lord Nelson’s flagship ‘Victory’.

-

1967

Alan Cosby Joins Kent Brushes

The late 1960s saw a key personnel change, with Eric’s son, Alan Cosby, taking over the reins alongside his production Manager, Tony Newman. Alan is still the Managing Director and Chairman today, currently serving his 57th year with the Company.

-

1970

Streamlining

In a bid to recover outstanding debts and bring the company into the 20th Century, Alan Cosby streamlined the London warehouses, factories and Bond Street Office, merging the whole business to the Apsley Factory. New lines were launched across retailers such as Boots and Superdrug, and in 1974, he designed the ‘Headhog’, which remains a bestseller to this day.

-

1980

Techy Times

Like his predecessors, Alan Cosby was always keen to stay up to date with technology and would eagerly invest in new computers and software. He introduced the bar-code system when it first came to the market, as well as telex, fax machines and mobile phones.

-

1990

A Great Friend Lost

In 1990, Tony Newman (Alan’s business partner) died suddenly from a brain haemorrhage. Alan elected to run the Company without a replacement, and by the 2000s, his hard work had paid off, with new markets secured both at home and abroad. These profits were used to reinvest in machinery, all of which are still used in the factory today.

-

2013

Movember

Alan Cosby’s son, Ben Cosby, joined the business in his early twenties and worked as Creative Director for over 20 years. He was heavily involved in the Movember campaign for which Kent Brushes made a comb. We sold a staggering 100,000 handmade ‘Mo Combs,’ raising valuable funds for the charity.

-

2017

Queen's Award for Enterprise

One of our most prestigious years in history saw Kent Brushes receive the Queen’s Award for Enterprise: International Trade, in recognition of our innovative designs and success in overseas markets. Not only that, but we also made the Financial Times’ Top 1000 list, marking the fastest-growing companies in Europe.

-

2025

Today - The Legacy Continues

In May 2022, Steve Wright was appointed as CEO of the Company, bringing with him more than 20 years of experience. In January 2024, Zoe Cosby, the daughter of Alan Cosby, joined the Company as Head of PR.

We were also awarded ‘Employer of the Year’ for Hertfordshire by ’Steps to Skills’ as well as receiving our ‘Disability Confident Employer’ certificate. As we head towards our 250th anniversary, the future looks bright for Kent Brushes. Our products are available in more than 50 countries worldwide, and we have new and exciting ranges to announce soon, so watch this space.

discover

OUR STORY

Founded by William Kent in 1777, Kent Brushes holds a

pre-eminent place in the history of brush making, with a nearly 250-year unbroken record of excellence in manufacturing. The Kent family continued to run the company for six generations until 1932 when the last of the three Kent brothers passed away. Mr Eric L.H Cosby, owner of Cosby Brushes Ltd, entered an association with G.B Kent & Sons and started a new chapter in Kent’s long history. Since then, Kent Brushes has been under the creative and dynamic direction of the Cosby family.